How to Maintain and Maximize the Life of a Spring

Proper maintenance and handling can significantly extend the life of a spring. Below are key practices to ensure their optimal performance and durability.

1. Select the Right Material and Design

Choosing the correct type of spring material for your application is critical. Factors such as environmental conditions, load requirements, and operating cycles should be considered. Common materials include stainless steel, high-carbon steel, and phosphor bronze, each offering different resistance to corrosion, fatigue, and stress.

2. Avoid Overloading

Exceeding a spring’s designed load capacity can cause permanent deformation or premature failure. Always ensure that the spring operates within its specified load limits. Consider using multiple springs or a higher-capacity spring if necessary.

3. Protect Against Corrosion

Exposure to moisture, chemicals, or extreme temperatures can weaken a spring over time. Use corrosion-resistant materials, coatings, or lubricants to protect against environmental damage. Regularly inspect springs for signs of rust and apply protective coatings as needed.

4. Implement Proper Lubrication

Friction and wear can shorten a spring’s lifespan. Applying a suitable lubricant reduces friction between coils and prevents wear and corrosion. Ensure that the lubricant used is compatible with the spring material and operating environment.

5. Avoid Excessive Cycling

Every spring has a finite number of cycles before fatigue failure occurs. Reducing the frequency and intensity of load cycles can prolong the spring’s usability. If high cycling is unavoidable, select a spring specifically designed for fatigue resistance.

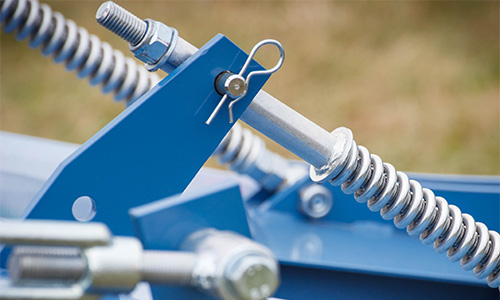

6. Handle Springs with Care

Improper handling can introduce defects that lead to premature failure. Avoid bending, twisting, or stretching springs beyond their limits during installation or maintenance. Use the correct tools and techniques to install and remove springs safely.

7. Regular Inspection and Maintenance

Periodically inspect springs for wear, deformation, or cracks. Address any signs of damage immediately to prevent system failures. Replacing worn-out springs before they break can help maintain operational efficiency and safety.

8. Store Springs Properly

When storing unused springs, keep them in a dry, temperature-controlled environment. Avoid stacking or compressing springs in a way that could cause deformation. Store them in their relaxed state to prevent unnecessary stress.

By following these best practices, you can maximize the life of your springs and ensure reliable performance in your applications. Proper maintenance not only extends spring longevity but also enhances safety and efficiency in mechanical systems.

Search Stock Springs

Request a Custom Quote

7 Tips to Maximize Spring Life Cycle

Preventing Torsion Spring Failures

Sign Up/Log In

Sign Up/Log In

.png)