HEFTY ™ Die Springs

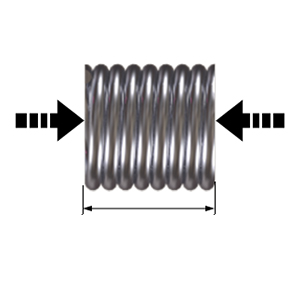

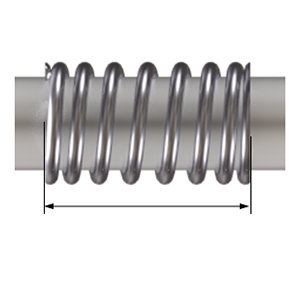

HEFTY™ Die Springs are heavy duty metal compression springs manufactured using round wire, specifically designed to be used as Die Springs or as heavy duty coil springs in any heavy stress, heavy load application. Lee Spring offers FIVE different types of HEFTY™ Die Springs, based on Load, for applications requiring Medium Duty up through Extra Heavy duty Die Springs. Learn more about HEFTY™ Die Spring and How to Measure a Compression Spring.

Engineering Notes & Tolerances

Spring Materials, Specifications & Data

Spring Coatings and Surface Treatments

Results 490 Springs

| Material | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

LHL 625C 06 |

1.499 |

0.59 |

14.99 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

6.35 |

2.5 |

63.5 |

30358.6 |

3035.86 |

30.359 |

3.0359 |

170 |

297.73 |

29.773 |

4.064 |

1.6 |

40.64 |

0.284 |

0.112 |

2.84 |

MW |

LHL 625C 08 |

1.499 |

0.59 |

14.99 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

8.89 |

3.5 |

88.9 |

21786.8 |

2178.68 |

21.787 |

2.1787 |

122 |

213.66 |

21.366 |

5.436 |

2.14 |

54.36 |

0.284 |

0.112 |

2.84 |

MW |

LHL 625AB 07 |

1.499 |

0.59 |

14.99 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

7.62 |

3 |

76.2 |

13929.2 |

1392.92 |

13.929 |

1.3929 |

78 |

136.60 |

13.66 |

4.343 |

1.71 |

43.43 |

0.249 |

0.098 |

2.49 |

MW |

LHL 625C 07 |

1.499 |

0.59 |

14.99 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

7.62 |

3 |

76.2 |

25715.5 |

2571.55 |

25.716 |

2.5716 |

144 |

252.19 |

25.219 |

4.674 |

1.84 |

46.74 |

0.284 |

0.112 |

2.84 |

MW |

LHL 625C 01 |

1.504 |

0.592 |

15.04 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

2.54 |

1 |

25.4 |

75717.9 |

7571.79 |

75.718 |

7.5718 |

424 |

742.56 |

74.256 |

1.753 |

0.69 |

17.53 |

0.277 |

0.109 |

2.77 |

MW |

LHL 625C 09 |

1.511 |

0.595 |

15.11 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

10.16 |

4 |

101.6 |

19286.6 |

1928.66 |

19.287 |

1.9287 |

108 |

189.14 |

18.914 |

6.756 |

2.66 |

67.56 |

0.292 |

0.115 |

2.92 |

MW |

LHL 625C 04 |

1.511 |

0.595 |

15.11 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

4.445 |

1.75 |

44.45 |

42859.2 |

4285.92 |

42.859 |

4.2859 |

240 |

420.32 |

42.032 |

2.972 |

1.17 |

29.72 |

0.284 |

0.112 |

2.84 |

MW |

LHL 625C 10 |

1.511 |

0.595 |

15.11 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

15.24 |

6 |

152.4 |

12500.6 |

1250.06 |

12.501 |

1.2501 |

70 |

122.59 |

12.259 |

10.109 |

3.98 |

101.09 |

0.292 |

0.115 |

2.92 |

MW |

LHL 625C 11 |

1.511 |

0.595 |

15.11 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

17.78 |

7 |

177.8 |

11429.1 |

1142.91 |

11.429 |

1.1429 |

64 |

112.09 |

11.209 |

11.532 |

4.54 |

115.32 |

0.292 |

0.115 |

2.92 |

MW |

LHL 625C 12 |

1.511 |

0.595 |

15.11 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

20.32 |

8 |

203.2 |

9821.9 |

982.19 |

9.822 |

0.9822 |

55 |

96.32 |

9.632 |

13.31 |

5.24 |

133.1 |

0.292 |

0.115 |

2.92 |

MW |

LHL 625C 9A |

1.511 |

0.595 |

15.11 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

12.7 |

5 |

127 |

16072.2 |

1607.22 |

16.072 |

1.6072 |

90 |

157.62 |

15.762 |

8.382 |

3.3 |

83.82 |

0.292 |

0.115 |

2.92 |

MW |

LHL 625C 02 |

1.524 |

0.6 |

15.24 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

3.175 |

1.25 |

31.75 |

52859.7 |

5285.97 |

52.86 |

5.286 |

296 |

518.39 |

51.839 |

2.184 |

0.86 |

21.84 |

0.277 |

0.109 |

2.77 |

MW |

LHL 625D 11 |

1.524 |

0.6 |

15.24 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

17.78 |

7 |

177.8 |

14286.4 |

1428.64 |

14.286 |

1.4286 |

80 |

140.11 |

14.011 |

11.786 |

4.64 |

117.86 |

0.305 |

0.12 |

3.05 |

MW |

LHL 625D 12 |

1.524 |

0.6 |

15.24 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

20.32 |

8 |

203.2 |

12143.4 |

1214.34 |

12.143 |

1.2143 |

68 |

119.09 |

11.909 |

13.97 |

5.5 |

139.7 |

0.305 |

0.12 |

3.05 |

MW |

LHL 625D 10 |

1.524 |

0.6 |

15.24 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

15.24 |

6 |

152.4 |

16072.2 |

1607.22 |

16.072 |

1.6072 |

90 |

157.62 |

15.762 |

9.779 |

3.85 |

97.79 |

0.305 |

0.12 |

3.05 |

MW |

LHL 625D 01 |

1.524 |

0.6 |

15.24 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

2.54 |

1 |

25.4 |

112505 |

11250.5 |

112.505 |

11.2505 |

630 |

1103.34 |

110.334 |

1.803 |

0.71 |

18.03 |

0.3 |

0.118 |

3 |

MW |

LHL 625D 08 |

1.524 |

0.6 |

15.24 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

8.89 |

3.5 |

88.9 |

28572.8 |

2857.28 |

28.573 |

2.8573 |

160 |

280.21 |

28.021 |

5.766 |

2.27 |

57.66 |

0.305 |

0.12 |

3.05 |

MW |

LHL 625D 06 |

1.524 |

0.6 |

15.24 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

6.35 |

2.5 |

63.5 |

39287.6 |

3928.76 |

39.288 |

3.9288 |

220 |

385.29 |

38.529 |

4.369 |

1.72 |

43.69 |

0.305 |

0.12 |

3.05 |

MW |

LHL 625D 09 |

1.524 |

0.6 |

15.24 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

10.16 |

4 |

101.6 |

24108.3 |

2410.83 |

24.108 |

2.4108 |

135 |

236.43 |

23.643 |

6.731 |

2.65 |

67.31 |

0.305 |

0.12 |

3.05 |

MW |

LHL 625D 05 |

1.524 |

0.6 |

15.24 |

1.588 |

0.625 |

15.88 |

0.874 |

0.344 |

8.74 |

5.08 |

2 |

50.8 |

51788.2 |

5178.82 |

51.788 |

5.1788 |

290 |

507.89 |

50.789 |

3.48 |

1.37 |

34.8 |

0.305 |

0.12 |

3.05 |

MW |

Pagination

.png)

Sign Up/Log In

Sign Up/Log In